At NovaCentrix, we believe that building the future of printed and flexible electronics isn’t just about developing cutting-edge technology—it’s about fostering strong industry partnerships. In this ongoing series, we’re highlighting the innovators who are pushing boundaries alongside us, helping to transform groundbreaking ideas into real-world solutions.

At NovaCentrix, we’re proud to support BotFactory’s vision by providing advanced materials solutions that enhance the performance and accessibility of their technology. Together, we are making electronics development faster, more efficient, and more sustainable—empowering innovators across industries to bring their ideas to life.

For this issue, we talk to CEO and Founder of BotFactory, Carlos Ospina Tarazona. Our questions to Carlos are in blue and his answers are in black below:

Hi Carlos, thank you so much for taking the time to chat with us! How about we start from the very beginning? Can you share a bit of the story behind the founding of BotFactory?

I founded an electronics company in Colombia in 2005. The company was building electronics for sensing filters in the transportation industry. While the market for the product was strong, the manufacturing capability for PCBs in Colombia was lacking. PCB prototypes had to be ordered from the USA, and those could easily take 30-40 days to arrive. The one thing startups can’t afford to waste, even more than money, is time… and there I was, waiting for weeks to get the prototypes, with a team of 20 people eagerly waiting to continue product development.

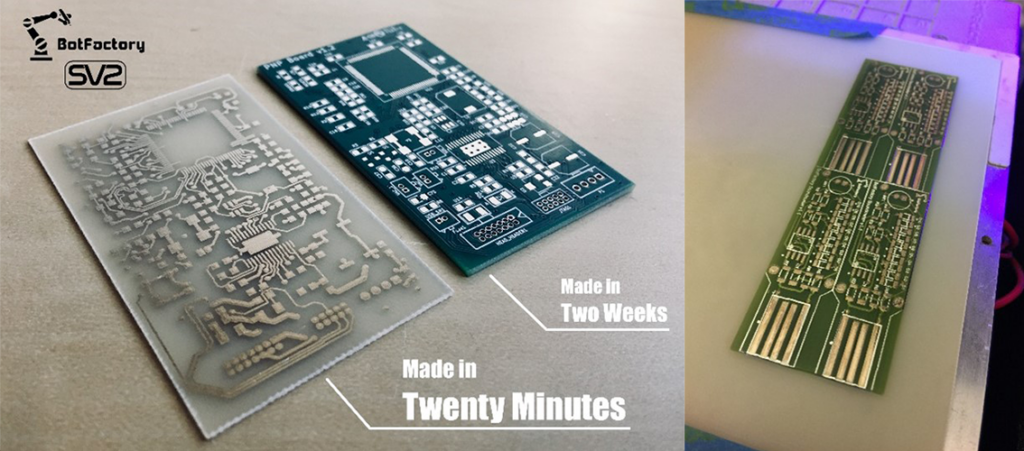

Fast forward to 2012, New York City was intoxicated by MakerBot and the promise of “3D printing everything.” It was then that I met Nicolas Vansnick and Michael Knox at NYU, and after winning the “INNOVENTION” contest, we decided to launch BotFactory. Our goal was to provide a technology that would allow people to create “Electronics here, and now,” democratizing PCB manufacturing and solving the headache for thousands of innovators around the world who needed to manufacture complex, multi-layer PCB prototypes as quickly as possible, even when the industrial infrastructure wasn’t there.

Tell us a little bit about BotFactory

BotFactory, Inc. is a New York City-based company, and we are revolutionizing electronics prototyping with our innovative desktop circuit board printers. Our flagship product, the SV2, integrates conductive ink printing, solder paste dispensing, and component placement, allowing users to rapidly prototype printed circuit boards (PCBs) in minutes—right from their desks. By streamlining the design process, we help engineers, educators, and makers iterate faster and reduce development time. Our technology makes PCB prototyping accessible, affordable, and environmentally friendly, driving a future where electronics manufacturing is faster, more efficient, and sustainable.

What is the material deposition process?

BotFactory printers utilize two distinct material deposition technologies. First, Drop-on-Demand inkjet technology deposits conductive and insulating materials to create multi-layered PCBs. This method achieves resolutions with traces and clearances as fine as 100µm. Inkjet technology ensures rapid and uniform layer coverage, enabling additive PCB manufacturing.

Second, an extrusion system, also known as direct-print, dispenses viscous materials like solder pastes or conductive glues. While BotFactory printers primarily use this to deposit solder paste on PCB pads, its versatility extends to other applications, making these systems among the most flexible printing solutions available.

What are the biggest advantages/ pain points that are solved?

Traditional PCB manufacturing is plagued by long lead times and high costs, especially for prototypes and low-volume production. BotFactory eliminates these pain points by bringing complex PCB fabrication right to your desktop. Our printers slash production times from days to mere hours, allowing for rapid iteration and experimentation. Imagine creating a prototype for the cost of a cup of coffee – that’s the power of BotFactory.

Beyond speed and affordability, our technology unlocks on-demand PCB printing in remote and challenging environments. Whether it’s a research station in the Arctic, a repair on a sea-platform operation, or even space exploration, BotFactory provides a reliable and accessible solution for electronics manufacturing where traditional methods simply aren’t feasible.

Which areas are customers coming from (technology or market space wise)?

Our customers are evenly distributed between R&D Labs in Commercial Companies, R&D Labs in Academia, R&D Labs in National Research Institutions and the DoD.

In terms of materials requirements can you elaborate?

For inkjet printing, we utilize silver nanoparticles as our primary conductive ink. We also employ polymer-based, UV-curable insulating inks. Inkjet printing necessitates complex chemistry, requiring low viscosity inks with a high enough particle content to create uniform, functional features. For instance, conductive traces must exhibit low resistivity, while insulating layers require high resistivity. In both cases, the printed structures need to perform reliably across various frequencies and under diverse electrical conditions.

Years of customer service have revealed a key insight: while material performance is important, ink reliability is paramount. Customers prioritize a ‘print-and-go’ experience, free from concerns about clogging, head damage, or unexpected failures. They value inks that consistently deliver predictable results, eliminating worries about nozzle drying, sedimentation, or inconsistent performance.

How does NovaCentrix’s inks meet those requirements? What are the advantages?

The Metalon® series of conductive inks has been invaluable in developing a consistent experience for our customers. While they may not always work perfectly out-of-the-box, NovaCentrix has consistently provided support, helping us fine-tune the inks to our requirements. Thanks to this collaboration, our customers enjoy inks that are easier to store and use. Most customers store these inks at room temperature, and cartridges often outlast their stipulated shelf life. Moreover, NovaCentrix’s inks are optimized for adhesion to specific substrates like FR4 and Kapton, enabling the highest possible printing resolution on these challenging materials.

Can you please elaborate on the partnership?

We have collaborated with NovaCentrix for over seven years. The primary advantage of this partnership has been their unwavering commitment to providing materials that meet our precise requirements, even if it entails developing multiple iterations of the same ink over several years of research.

Moreover, we are fostering a relationship of trust and mutual respect that extends beyond the laboratory. This collaboration is poised to benefit both companies, driving success in our respective markets through diverse initiatives.

The synergy between NovaCentrix and BotFactory is fueling a revolution in electronics manufacturing. Our collaborative innovations are ushering in a future where printed electronics transcend the limitations of traditional fabrication. Imagine a world where flexible circuits are seamlessly integrated into clothing, powering wearable sensors that monitor our health and connect us to the digital world. Envision lightweight, customizable sensors embedded in everyday objects, revolutionizing how we interact with our environment. This is the future that printed electronics promises – a future where functionality is no longer constrained by rigid boards and complex manufacturing processes.

Through groundbreaking material science, NovaCentrix’s advanced inks empower BotFactory’s desktop printers to produce high-performance circuits with unprecedented speed and precision. This convergence of technology is democratizing electronics development, enabling a new generation of innovators to bring their ideas to life with ease and sustainability. As material science continues to push boundaries, we can expect even more astonishing advancements in printed electronics, blurring the lines between the physical and digital worlds and shaping a future limited only by our imagination.