Over the years, nScrypt has worked closely with both NovaCentrix and our sister company, PulseForge, contributing significantly to the advancement of high-tech additive manufacturing and next-generation electronics assembly.

A true pioneer in the field, nScrypt continues to lead with vision and technical excellence. We recently had the pleasure of speaking with Ken Church, CEO and founder of nScrypt, for an in-depth conversation.

Our questions are presented in blue, with Ken’s responses in black below.

Tell us a little bit about how nScrypt began and what challenges it was trying to address?

nScrypt was born out of groundbreaking research conducted under the DARPA Mesoscale Integrated Circuit Electronics (MICE) program in 1999. This program aimed to explore new frontiers in electronic packaging, specifically by merging printed electronics with 3D printing. The result of this initiative led to the formation of nScrypt as a spin-off from Sciperio, a company that had been at the forefront of this innovative work.

From the very beginning, nScrypt set out to address key challenges in the evolution of electronic manufacturing. Traditional printed circuit boards (PCBs) were inherently limited to planar designs, restricting their applications and integration into complex geometries. Our early research, in collaboration with Sciperio and the University of South Florida, focused on the feasibility of fabricating interconnects, resistors, and inductors directly into 3D-printed materials as an integrated process. This groundbreaking approach paved the way for a shift from conventional PCBs to fully integrated printed circuit structures, enabling the creation of non-planar electronics with unprecedented design flexibility.

Can you give an overview of where nScrypt fits in the additive manufacturing space?

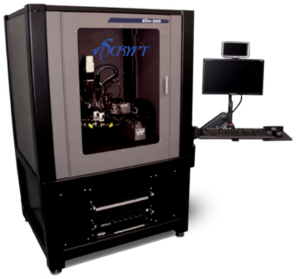

nScrypt is a leader in industrial precision microdispensing and advanced 3D manufacturing, delivering high-accuracy solutions for a wide range of industries. Founded in 2002 and based in Orlando, FL, nScrypt specializes in microdispensing. The company’s next-generation manufacturing equipment enables the creation of complex, functional products—including 3D-printed electronics, flexible circuits, and microelectronics—without manual tool changes. Our customizable platforms offer exceptional precision, multiple manufacturing options, and advanced features such as pick and place, conformal printing, and multi-material processing.

When we talk about nScrypt, we often hear about microdispensing and how it enables precision dispensing at its finest. Tell us more about the microdispensing process and how nScrypt has pushed the boundary of that technology.

How do the advantages of microdispensing process you mention solve manufacturing challenges across industries?

nScrypt’s technology provides solutions to some of the most pressing challenges in modern manufacturing. By offering reliable and highly accurate dispensing, the company enables advancements in electronics, bioprinting, and beyond. Its ability to print conformally—directly onto curved surfaces—opens up new possibilities for applications such as reducing wiring in electronics and creating intricate 3D structures that integrate electrical circuits directly into printed outputs. Unlike traditional 3D printers that are restricted to certain materials and geometric constraints, nScrypt’s systems work with a broad spectrum of materials, including low-viscosity solutions, metal inks, and solid polymers.

How does NovaCentrix’s material offerings fit into this?

nScrypt’s ability to work with a wide variety of liquid-to-paste materials is one of its standout advantages. The company’s sweet spot lies in pastes, which contain more nano/micro particles in a carrier than traditional inks. NovaCentrix’s inks align perfectly with these requirements, offering excellent pastes that process at low temperatures and perform exceptionally well in terms of conductivity and flow consistency. This synergy ensures that manufacturers can achieve the highest levels of performance in their applications.

Please tell us a little bit more about how this partnership plays a role in the technological advancement of the ecosystem.

The partnership between nScrypt and NovaCentrix is a crucial component of a larger equation. As part of a three-way collaboration, nScrypt provides the hardware, NovaCentrix supplies the materials, and customers bring the application needs. Together, these elements form a powerful ecosystem that drives innovation in high-tech manufacturing.

In an industry where precision, material versatility, and advanced functionality define success, nScrypt stands out as a transformative force. Whether in next-generation electronics, bioprinting, or high-tech sensors, the company’s technology is poised to drive significant advancements in multiple fields. With its unique capabilities and strategic partnerships, nScrypt is not just an industry leader—it is a vision for the future of manufacturing.