PulseForge Lift-Off: A Flashlamp Lift-Off Process

- What is PulseForge® Lift-Off (PFLO)? How is it used in industry?

PulseForge Lift-Off (PFLO) is a flashlamp based lift-off process developed by NovaCentrix to address the industrial need to rapidly and economically release polymeric films from rigid glass carriers. Developed as a laser lift-off (LLO) alternative, some of the advantages of PFLO include: (1) Enabling higher throughput by large-area illumination of the substrates as opposed to highly localized illumination in LLO process. (2) Light absorber on glass carrier increases process reliability and yield by ensuring no direct illumination of the polymeric film and the device stack. (3) Resiliency to pinholes and particle defects on the polymeric film coating as the film does not see any illumination.

Some industries that use PFLO are flexible display manufacturing, flexible sensors and batteries manufacturing, thin silicon wafer debonding in multi-layered 3D chip packages, and in other light-weight electronics packaging applications.

- How does PFLO differ from LLO?

Instead of using an excimer laser beam, the PFLO process uses high-intensity light from a flashlamp to release a polymeric film from a glass carrier. The main difference between the excimer LLO and PFLO process is the presence of a light absorber layer on the carrier glass. Most, but not all, polymeric films have strong absorption of UV light, thus enabling the excimer laser beam (operating in UV) to be directly absorbed at the polymer-glass interface in LLO process. In contrast, the light from the PFLO process has a broader wavelength (mid UV to near IR). One of the primary functions of the coated absorber layer is to prevent the transmission of the light through the polymeric substrate. In addition, PFLO also relies on strong absorption of the light by the absorber layer to promote necessary heating for the release of the polymeric film.

- What is the mechanism of PFLO?

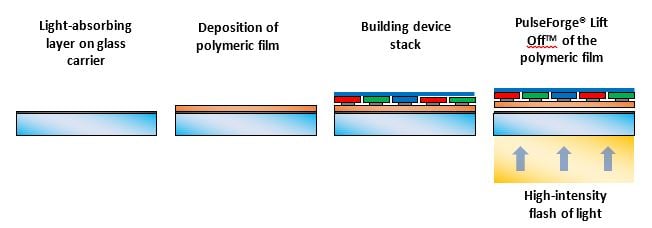

The key mechanism in PFLO is the thermal vaporization of the polymeric film at the polymeric film-absorber layer coated carrier glass interface. Consider the figure below, the carrier glass in the PFLO process is first coated with a thin film (100 nm – 300 nm) of light absorber layer. The polymeric film intended to be released is coated directly on the top of this layer and the device stack is built. The light absorber layer absorbs the high intensity light flashed through the glass to promote heating over a very short period of time (micro-seconds). Heat conduction from the absorber layer to the polymer layer vaporizes the polymer only at the interface, resulting in an adhesion loss of the polymer layer, which is then mechanically released. Further, as result of rapid thermal heating, thermal expansion mismatch between coated polymeric film and the absorber layer coated glass may assist in easy release of the polymeric film.

- What is the estimated local temperature rise on the absorber layer?

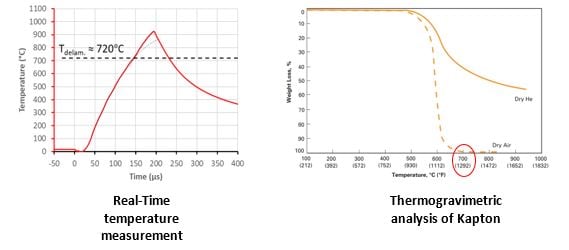

The peak temperature achieved on the absorber layer during the PFLO process is typically higher than the degradation temperature of the polymeric film. This high temperature is achieved for only a short period of time (100-200 µs). As the time period of lift-off is very short, and there is no thermal contact between the absorber layer and the device stack after the process, the device stack remains relatively cool. To understand this, consider the real-time temperature measurement data (see below) obtained during PFLO of the standard polyimide (PI) coating as an example. In-situ temperature measurements were made at the absorber/PI interface using a temperature sensor with the same sensing element as the typical absorber layer material. A temperature rise of up to 950°C was recorded over ≈ 150 µs. The temperature is then quickly conducted away from the interface. The peak temperature is above the degradation temperature of the PI (Kapton) as shown below in the TGA data, indicating that the lift-off (delamination) could’ve occurred at around 720°C. Any residual heat after the lift-off on the absorber layer is conducted to the glass carrier as there is no thermal contact between the absorber layer and the polymer.

- Why does the top of the device stack remain cooler? What is the temperature achieved on the top of the device stack during PFLO process?

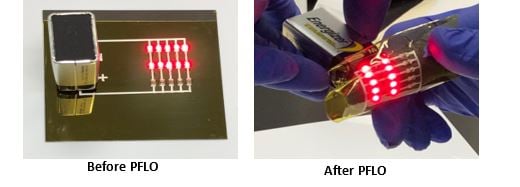

PFLO process is a self-limiting process, as soon the polymeric film is released from the absorber layer coated glass substrate, the thermal transport towards the bulk of the film is limited due to poor thermal contact between the released polymer and the substrate. Consequently, any residual heat on the absorber layer is quickly conducted into the glass carrier substrate instead of to the device stack. Thermal conduction from absorber to carrier substrate continues until they equilibrate. All these factors play a vital role in keeping the top of the device stack relatively cooler. For instance, the LED array developed on the coated PI film (shown below) is still functional after the PI film with the device stack was released using PFLO process. Besides this, our recent studies with in-situ temperature measurements have shown that the temperature achieved on the top of the device stack is not greater than 80°C.

- Can different types of polymers be released without having to change the structure of the lift-off substrate and the lift-off equipment??

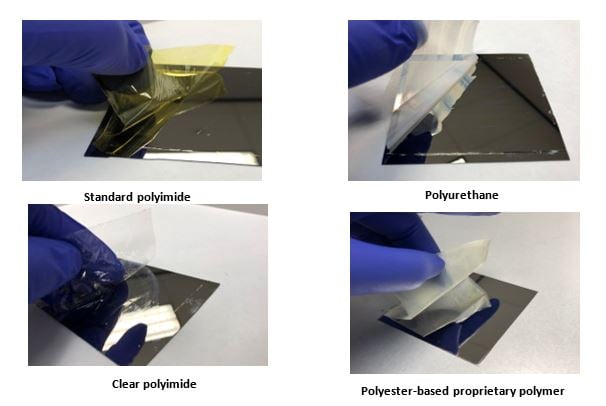

Presence of the light absorbing layer enables the PFLO process to be polymer agnostic. A wide variety of both thermoset and thermoplastic polymeric films have been tested with PFLO and have been successfully released from the same carrier substrate. Some of the polymeric films that were released using PFLO are shown below. These films were released using the same PulseForge equipment.

You can find the complete paper on PulseForge Lift-Off here, with additional Q&A and results.

.png?width=100&height=100&name=Vikram%20(2).png)